Flash memory is non-volatile, which means that no power is needed to maintain the information stored in the chip. In addition, flash memory offers fast read access times (although not as fast as volatile DRAM memory used for main memory in PCs) and better kinetic shock resistance than hard disks. These characteristics explain the popularity of flash memory in portable devices. Another feature of flash memory is that when packaged in a "memory card," it is enormously durable, being able to withstand intense pressure, extremes of temperature, and even immersion in water.

Although technically a type of EEPROM, the term "EEPROM" is generally used to refer specifically to non-flash EEPROM which is erasable in small blocks, typically bytes. Because erase cycles are slow, the large block sizes used in flash memory erasing give it a significant speed advantage over old-style EEPROM when writing large amounts of data.

History

Flash memory (both NOR and NAND types) was invented by Dr. Fujio Masuoka while working for Toshiba circa 1980.[1][2] According to Toshiba, the name "flash" was suggested by Dr. Masuoka's colleague, Mr. Shoji Ariizumi, because the erasure process of the memory contents reminded him of a flash of a camera. Dr. Masuoka presented the invention at the IEEE 1984 International Electron Devices Meeting (IEDM) held in San Francisco, California.Intel saw the massive potential of the invention and introduced the first commercial NOR type flash chip in 1988.[3] NOR-based flash has long erase and write times, but provides full address and data buses, allowing random access to any memory location. This makes it a suitable replacement for older ROM chips, which are used to store program code that rarely needs to be updated, such as a computer's BIOS or the firmware of set-top boxes. Its endurance is 10,000 to 1,000,000 erase cycles.[4] NOR-based flash was the basis of early flash-based removable media; CompactFlash was originally based on it, though later cards moved to less expensive NAND flash.

Toshiba announced NAND flash at ISSCC in 1989. It has faster erase and write times, and requires a smaller chip area per cell, thus allowing greater storage densities and lower costs per bit than NOR flash; it also has up to ten times the endurance of NOR flash. However, the I/O interface of NAND flash does not provide a random-access external address bus. Rather, data must be read on a block-wise basis, with typical block sizes of hundreds to thousands of bits. This made NAND flash unsuitable as a drop-in replacement for program ROM since most microprocessors and microcontrollers required byte-level random access. In this regard NAND flash is similar to other secondary storage devices such as hard disks and optical media, and is thus very suitable for use in mass-storage devices such as memory cards. The first NAND-based removable media format was SmartMedia, and many others have followed, including MultiMediaCard, Secure Digital, Memory Stick and xD-Picture Card. A new generation of memory card formats, including RS-MMC, miniSD and microSD, and Intelligent Stick, feature extremely small form factors. For example, the microSD card has an area of just over 1.5 cm², with a thickness of less than 1 mm; microSD capacities range from 64MB to 64GB, as of October 2008.[citation needed]

Principles of operation

Flash memory stores information in an array of memory cells made from floating-gate transistors. In traditional single-level cell (SLC) devices, each cell stores only one bit of information. Some newer flash memory, known as multi-level cell (MLC) devices, can store more than one bit per cell by choosing between multiple levels of electrical charge to apply to the floating gates of its cells.NOR flash

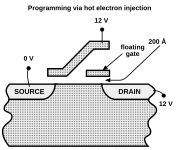

In NOR gate flash, each cell resembles a standard MOSFET, except the transistor has two gates instead of one. On top is the control gate (CG), as in other MOS transistors, but below this there is a floating gate (FG) insulated all around by an oxide layer. The FG is interposed between the CG and the MOSFET channel. Because the FG is electrically isolated by its insulating layer, any electrons placed on it are trapped there and, under normal conditions, will not discharge for many years. When the FG holds a charge, it screens (partially cancels) the electric field from the CG, which modifies the threshold voltage (VT) of the cell. During read-out, a voltage is applied to the CG, and the MOSFET channel will become conducting or remain insulating, depending on the VT of the cell, which is in turn controlled by charge on the FG. The current flow through the MOSFET channel is sensed and forms a binary code, reproducing the stored data. In a multi-level cell device, which stores more than one bit per cell, the amount of current flow is sensed (rather than simply its presence or absence), in order to determine more precisely the level of charge on the FG.A single-level NOR flash cell in its default state is logically equivalent to a binary "1" value, because current will flow through the channel under application of an appropriate voltage to the control gate. A NOR flash cell can be programmed, or set to a binary "0" value, by the following procedure:

- an elevated on-voltage (typically >5 V) is applied to the CG

- the channel is now turned on, so electrons can flow from the source to the drain (assuming an NMOS transistor)

- the source-drain current is sufficiently high to cause some high energy electrons to jump through the insulating layer onto the FG, via a process called hot-electron injection

Despite the need for high programming and erasing voltages, virtually all flash chips today require only a single supply voltage, and produce the high voltages via on-chip charge pumps.

NAND flash

NAND gate flash uses tunnel injection for writing and tunnel release for erasing. NAND flash memory forms the core of the removable USB storage devices known as USB flash drives, most memory card formats available today and many Nintendo DS storage devices such as N-Card.Limitations

Block erasure

One limitation of flash memory is that although it can be read or programmed a byte or a word at a time in a random access fashion, it must be erased a "block" at a time. This generally sets all bits in the block to 1. Starting with a freshly erased block, any location within that block can be programmed. However, once a bit has been set to 0, only by erasing the entire block can it be changed back to 1. In other words, flash memory (specifically NOR flash) offers random-access read and programming operations, but cannot offer arbitrary random-access rewrite or erase operations. A location can, however, be rewritten as long as the new value's 0 bits are a superset of the over-written value's. For example, a nibble value may be erased to 1111, then written as 1110. Successive writes to that nibble can change it to 1010, then 0010, and finally 0000. In practice few algorithms can take advantage of this successive write capability and in general the entire block is erased and rewritten at once.Although data structures in flash memory cannot be updated in completely general ways, this allows members to be "removed" by marking them as invalid. This technique must be modified somewhat for multi-level devices, where one memory cell holds more than one bit.

Memory wear

Another limitation is that flash memory has a finite number of erase-write cycles. Most commercially available flash products are guaranteed to withstand around 100,000 write-erase-cycles.[citation needed] The guaranteed cycle count may apply only to block zero (as is the case with TSOP NAND parts), or to all blocks (as in NOR). This effect is partially offset in some chip firmware or file system drivers by counting the writes and dynamically remapping blocks in order to spread write operations between sectors; this technique is called wear levelling. Another approach is to perform write verification and remapping to spare sectors in case of write failure, a technique called bad block management (BBM). For portable consumer devices, these wearout management techniques typically extend the life of the flash memory beyond the life of the device itself, and some data loss may be acceptable in these applications. For high reliability data storage, however, it is not advisable to use flash memory that has been through a large number of programming cycles. This limitation does not apply to 'read-only' applications such as thin clients and routers, which are only programmed once or at most a few times during their lifetime.Low-level access

The low-level interface to flash memory chips differs from those of other memory types such as DRAM, ROM, and EEPROM, which support bit-alterability (both zero to one and one to zero) and random-access via externally accessible address buses.While NOR memory provides an external address bus for read and program operations (and thus supports random-access); unlocking and erasing NOR memory must proceed on a block-by-block basis. With NAND flash memory, read and programming operations must be performed page-at-a-time while unlocking and erasing must happen in block-wise fashion.

NOR memories

Reading from NOR flash is similar to reading from random-access memory, provided the address and data bus are mapped correctly. Because of this, most microprocessors can use NOR flash memory as execute in place (XIP) memory, meaning that programs stored in NOR flash can be executed directly without the need to first copy the program into RAM. NOR flash may be programmed in a random-access manner similar to reading. Programming changes bits from a logical one to a zero. Bits that are already zero are left unchanged. Erasure must happen a block at a time, and resets all the bits in the erased block back to one. Typical block sizes are 64, 128, or 256 kiB.Bad block management is a relatively new feature in NOR chips. In older NOR devices not supporting bad block management, the software or device driver controlling the memory chip must correct for blocks that wear out, or the device will cease to work reliably.

The specific commands used to lock, unlock, program, or erase NOR memories differ for each manufacturer. To avoid needing unique driver software for every device made, a special set of CFI commands allow the device to identify itself and its critical operating parameters.

Apart from being used as random-access ROM, NOR memories can also be used as storage devices by taking advantage of random-access programming. Some devices offer read-while-write functionality so that code continues to execute even while a program or erase operation is occurring in the background. For sequential data writes, NOR flash chips typically have slow write speeds compared with NAND flash.

NAND memories

NAND flash architecture was introduced by Toshiba in 1989. These memories are accessed much like block devices such as hard disks or memory cards. Each block consists of a number of pages. The pages are typically 512[5] or 2,048 or 4,096 bytes in size. Associated with each page are a few bytes (typically 12–16 bytes) that should be used for storage of an error detection and correction checksum.Typical block sizes include:

32 pages of 512 bytes each for a block size of 16 kiB

64 pages of 2,048 bytes each for a block size of 128 kiB

64 pages of 4,096 bytes each for a block size of 256 kiB

128 pages of 4,096 bytes each for a block size of 512 kiB

While reading and programming is performed on a page basis, erasure can only be performed on a block basis. Another limitation of NAND flash is data in a block can only be written sequentially. Number of Operations (NOPs) is the number of times the sectors can be programmed. So far this number for MLC flash is always one whereas for SLC flash it is four.[citation needed]

NAND devices also require bad block management by the device driver software, or by a separate controller chip. SD cards, for example, include controller circuitry to perform bad block management and wear leveling. When a logical block is accessed by high-level software, it is mapped to a physical block by the device driver or controller. A number of blocks on the flash chip may be set aside for storing mapping tables to deal with bad blocks, or the system may simply check each block at power-up to create a bad block map in RAM. The overall memory capacity gradually shrinks as more blocks are marked as bad.

NAND relies on ECC to compensate for bits that may spontaneously fail during normal device operation. This ECC may correct as little as one bit error in each 2048 bits, or up to 22 bits in each 2048 bits [6]. If ECC cannot correct the error during read, it may still detect the error. When doing erase or program operations, the device can detect blocks that fail to program or erase and mark them bad. The data is then written to a different, good block, and the bad block map is updated.

Most NAND devices are shipped from the factory with some bad blocks which are typically identified and marked according to a specified bad block marking strategy. By allowing some bad blocks, the manufacturers achieve far higher yields than would be possible if all blocks had to be verified good. This significantly reduces NAND flash costs and only slightly decreases the storage capacity of the parts.

When executing software from NAND memories, virtual memory strategies are often used: memory contents must first be paged or copied into memory-mapped RAM and executed there (leading to the common combination of NAND + RAM). A memory management unit (MMU) in the system is helpful, but this can also be accomplished with overlays. For this reason, some systems will use a combination of NOR and NAND memories, where a smaller NOR memory is used as software ROM and a larger NAND memory is partitioned with a file system for use as a nonvolatile data storage area.

NAND is best suited to systems requiring high capacity data storage. This type of flash architecture offers higher densities and larger capacities at lower cost with faster erase, sequential write, and sequential read speeds, sacrificing the random-access and execute in place advantage of the NOR architecture.

Standardization

A group called the Open NAND Flash Interface Working Group (ONFI) has developed a standardized low-level interface for NAND flash chips. This allows interoperability between conforming NAND devices from different vendors. The ONFI specification version 1.0[7] was released on December 28, 2006. It specifies:- a standard physical interface (pinout) for NAND flash in TSOP-48, WSOP-48, LGA-52, and BGA-63 packages

- a standard command set for reading, writing, and erasing NAND flash chips

- a mechanism for self-identification (comparable to the Serial Presence Detection feature of SDRAM chips)

A group of vendors, including Intel, Dell, and Microsoft formed a Non-Volatile Memory Host Controller Interface (NVMHCI) Working Group.[9] The goal of the group is to provide standard software and hardware programming interfaces for nonvolatile memory subsystems, including the "flash cache" device connected to the PCI Express bus.

Distinction between NOR and NAND flash

NOR and NAND flash differ in two important ways:- the connections of the individual memory cells are different

- the interface provided for reading and writing the memory is different (NOR allows random-access for reading, NAND allows only page access)

NOR and NAND flash get their names from the structure of the interconnections between memory cells.[10] In NOR flash, cells are connected in parallel to the bit lines, allowing cells to be read and programmed individually. The parallel connection of cells resembles the parallel connection of transistors in a CMOS NOR gate. In NAND flash, cells are connected in series, resembling a NAND gate, and preventing cells from being read and programmed individually: the cells connected in series must be read in series.

When NOR flash was developed, it was envisioned as a more economical and conveniently rewritable ROM than contemporary EPROM, EAROM, and EEPROM memories. Thus random-access reading circuitry was necessary. However, it was expected that NOR flash ROM would be read much more often than written, so the write circuitry included was fairly slow and could only erase in a block-wise fashion; random-access write circuitry would add to the complexity and cost unnecessarily.

Because of the series connection and removal of wordline contacts, a large grid of NAND flash memory cells will occupy perhaps only 60% of the area of equivalent NOR cells[11] (assuming the same CMOS process resolution, e.g. 130 nm, 90 nm, 65 nm). NAND flash's designers realized that the area of a NAND chip, and thus the cost, could be further reduced by removing the external address and data bus circuitry. Instead, external devices could communicate with NAND flash via sequential-accessed command and data registers, which would internally retrieve and output the necessary data. This design choice made random-access of NAND flash memory impossible, but the goal of NAND flash was to replace hard disks, not to replace ROMs.

Write Endurance

The write endurance of SLC Floating Gate NOR flash is typically equal or greater than that of NAND flash, while MLC NOR & NAND Flash have similar Endurance capabilities. Example Endurance cycle ratings listed in datasheets for NAND and NOR Flash are provided.- NAND Flash is typically rated at about 100K cycles (Samsung OneNAND KFW4G16Q2M)

- SLC Floating Gate NOR Flash has typical Endurance rating of 100K to 1,000K cycles (Numonyx M58BW 100K; Spansion S29CD016J 1000K)

- MLC Floating Gate NOR has typical Endurance rating of 100K cycles (Numonyx J3 Flash)

Flash file systems

Because of the particular characteristics of flash memory, it is best used with either a controller to perform wear-levelling and error correction or specifically designed file systems which spread writes over the media and deal with the long erase times of NOR flash blocks. The basic concept behind flash file systems is: When the flash store is to be updated, the file system will write a new copy of the changed data over to a fresh block, remap the file pointers, then erase the old block later when it has time.One of the earliest flash file systems was Microsoft's FFS2 (presumably preceded by FFS1), for use with MS-DOS in the early 1990s.[12]

Around 1994, the PCMCIA, an industry group, approved the Flash Translation Layer (FTL) specification, which allowed a Linear Flash device to look like a FAT disk, but still have effective wear levelling. Other commercial systems such as FlashFX and FlashFX Pro by Datalight were created to avoid patent concerns with FTL.

ZFS by Sun Microsystems has been optimized to manage Flash SSD systems, both as cache as well as main storage facilities, available for OpenSolaris, FreeBSD, and Mac OS X operating systems. Sun has announced a complete line of Flash enabled systems and storage devices.

JFFS was the first flash-specific file system for Linux, but it was quickly superseded by JFFS2, originally developed for NOR flash. Then YAFFS was released in 2002, dealing specifically with NAND flash, and JFFS2 was updated to support NAND flash too.

In practice, flash file systems are only used for "Memory Technology Devices" ("MTD"), which are embedded flash memories that do not have a controller. Removable flash memory cards and USB flash drives have built-in controllers to perform wear-levelling and error correction so use of a specific flash file system does not add any benefit. These removable flash memory devices use the FAT file system to allow universal compatibility with computers, cameras, PDAs and other portable devices with memory card slots or ports.

Capacity

Multiple chips are often arrayed to achieve higher capacities for use in consumer electronic devices such as multimedia player or GPS. The capacity of flash chips generally follows Moore's Law because they are manufactured with many of the same integrated circuits techniques and equipment.Consumer flash drives typically have sizes measured in powers of two (e.g. 512 MB, 8 GB). This includes SSD's as hard drive replacements, even though traditional hard drives tend to use decimal units. Thus, a 64GB SSD is actually 64 gibibytes (using binary units), even though many stores frequently advertise these units as 64 gigabytes. In reality, there is less than this amount due to overhead, such as disk formatting.

In 2005, Toshiba and SanDisk developed a NAND flash chip capable of storing 1 GB of data using Multi-level Cell (MLC) technology, capable of storing 2 bits of data per cell. In September 2005, Samsung Electronics announced that it had developed the world’s first 2 GB chip.[13]

In March 2006, Samsung announced flash hard drives with a capacity of 4 GB, essentially the same order of magnitude as smaller laptop hard drives, and in September 2006, Samsung announced an 8 GB chip produced using a 40 nanometer manufacturing process.[14]

In January 2008 Sandisk announced availability of their 12GB MicroSDHC and 32GB SDHC Plus cards.[15][16]

Transfer rates

Commonly advertised is the maximum read speed, NAND flash memory cards are generally faster at reading than writing.Transferring multiple small files, smaller than the chip specific block size, could lead to much lower rate.

Access latency has an influence on performance but is less of an issue than with their hard drive counterpart.

Sometimes denoted in MB/s (megabyte per second), or in number of "X" like 60x 100x or 150x. "X" speed rating makes reference to the speed at which a legacy audio CD drive would deliver data, 1x is equal to 150 kibibytes per second.

For example, a 100x memory card goes to 150 KiB x 100 = 15000 KiB per second = 14.65 MiB per second.

Note that the exact speed depends on whether the marketer means 106 bytes or 220 bytes by "megabyte".

Applications

Serial flash

Serial flash is a small, low-power flash memory that uses a serial interface, typically SPI, for sequential data access. When incorporated into an embedded system, serial flash requires fewer wires on the PCB than parallel flash memories, since it transmits and receives data one bit at a time. This may permit a reduction in board space, power consumption, and total system cost.There are several reasons why a serial device, with fewer external pins than a parallel device, can significantly reduce overall cost:

- Many ASICs are pad-limited, meaning that the size of the die is constrained by the number of wire bond pads, rather than the complexity and number of gates used for the device logic. Eliminating bond pads thus permits a more compact integrated circuit, on a smaller die; this increases the number of dies that may be fabricated on a wafer, and thus reduces the cost per die.

- Reducing the number of external pins also reduces assembly and packaging costs. A serial device may be packaged in a smaller and simpler package than a parallel device.

- Smaller and lower pin-count packages occupy reduced PCB area.

- Lower pin-count devices simplify PCB routing.

Firmware storage

With the increasing speed of modern CPUs, parallel flash devices are often much slower than the memory bus of the computer they are connected to. Conversely, modern SRAM offers access times below 10 ns, while DDR2 SDRAM offers access times below 20 ns. Because of this, it is often desirable to shadow code stored in flash into RAM; that is, the code is copied from flash into RAM before execution, so that the CPU may access it at full speed. Device firmware may be stored in a serial flash device, and then copied into SDRAM or SRAM when the device is powered-up.[17] Using an external serial flash device rather than on-chip flash removes the need for significant process compromise (a process that is good for high speed logic is generally not good for flash and vice-versa). Once it is decided to read the firmware in as one big block it is common to add compression to allow a smaller flash chip to be used. Typical applications for serial flash include storing firmware for hard drives, Ethernet controllers, DSL modems, wireless network devices, etc.Flash memory as a replacement for hard drives

There remain some aspects of flash-based SSDs that make the idea unattractive. Most important, the cost per gigabyte of flash memory remains significantly higher than that of platter-based hard drives. Although this ratio is decreasing rapidly for flash memory, it is not yet clear that flash memory will catch up to the capacities and affordability offered by platter-based storage. Still, research and development is sufficiently vigorous that it is not clear that it will not happen, either.[citation needed]

There is also some concern that the finite number of erase/write cycles of flash memory would render flash memory unable to support an operating system. This seems to be a decreasing issue as warranties on flash-based SSDs are approaching those of current hard drives.[18][19]

As of May 24, 2006, South Korean consumer-electronics manufacturer Samsung Electronics had released the first flash-memory based PCs, the Q1-SSD and Q30-SSD, both of which have 32 GB SSDs.[20] Dell Computer introduced the Latitude D430 laptop with 32 GB flash-memory storage in July 2007 -- at a price significantly above a hard-drive equipped version.[citation needed]

At the Las Vegas CES 2007 Summit Taiwanese memory company A-DATA showcased SSD hard disk drives based on Flash technology in capacities of 32 GB, 64 GB and 128 GB.[21] Sandisk announced an OEM 32 GB 1.8" SSD drive at CES 2007.[22] The XO-1, developed by the One Laptop Per Child (OLPC) association, uses flash memory rather than a hard drive. As of June 2007, a South Korean company called Mtron claims the fastest SSD with sequential read/write speeds of 100 MB/80 MB per second.[23]

Rather than entirely replacing the hard drive, hybrid techniques such as hybrid drive and ReadyBoost attempt to combine the advantages of both technologies, using flash as a high-speed cache for files on the disk that are often referenced, but rarely modified, such as application and operating system executable files. Also, Addonics has a PCI adapter for 4 CF cards,[24] creating a RAID-able array of solid-state storage that is much cheaper than the hardwired-chips PCI card kind.

The ASUS Eee PC uses a flash-based SSD of 2GB to 20GB, depending on model. The Apple Inc. Macbook Air has the option to upgrade the standard hard drive to a 64GB Solid State hard drive. The Lenovo ThinkPad X300 also features a built-in 64GB Solid State Drive.

Industry

One source states that, in 2008, the flash memory industry includes about US$9.1 billion in production and sales. Apple Inc. is the third largest purchaser of flash memory, consuming about 13% of production by itself.[25] Other sources put the flash memory market at a size of more than US$20 billion dollars in 2006, accounting for more than eight percent of the overall semiconductor market and more than 34 percent of the total semiconductor memory market.[26]Flash scalability

Due to its relatively simple structure and high demand for higher capacity, NAND Flash memory is the most aggressively scaled technology among electronic devices. The heavy competition among the top few manufacturers only adds to the aggression. Current projections show the technology to reach ~20 nm by ~2010. While the expected shrink timeline is a factor of two every three years per original version of Moore's law, this has recently been accelerated in the case of NAND flash to a factor of two every two years.

As the feature size of Flash memory cells reach the minimum limit (currently estimated ~20 nm), further Flash density increases will be driven by greater levels of MLC, possibly 3-D stacking of transistors, and process improvements. Even with these advances, it may be impossible to economically scale Flash to smaller and smaller dimensions. Many promising new technologies (such as FeRAM, MRAM, PMC, PCM, and others) are under investigation and development as possible more scalable replacements for Flash.[27]